Innovation and research

Thanks to our know- how, we carry out the most technologically advanced projects, beginning with an idea and implementing them finally. The production

of SADDAR Eco- anchors required a technology to be developed for production of high- strength PET plastic, that is modified by several chemical components and reinforced with glass fibres. The shape and dimensions of the SADDAR Eco-anchors have been designed by the inventor in such a way that:

- there are the thickened cross- sections in all places where breaking, bending and impact stresses have to be endured

- in the areas critical for functionality, the SADDAR Eco-anchors are several times thicker than steel sheet anchors

The result has been as follows:

- The material of SADDAR Eco- anchor needs to endure 2- TIMES lower maximum stresses This means that the anchor also has a higher maximum strength than a steel anchor.

- optimized shape higher strength than welded anchors made of steel sheet.

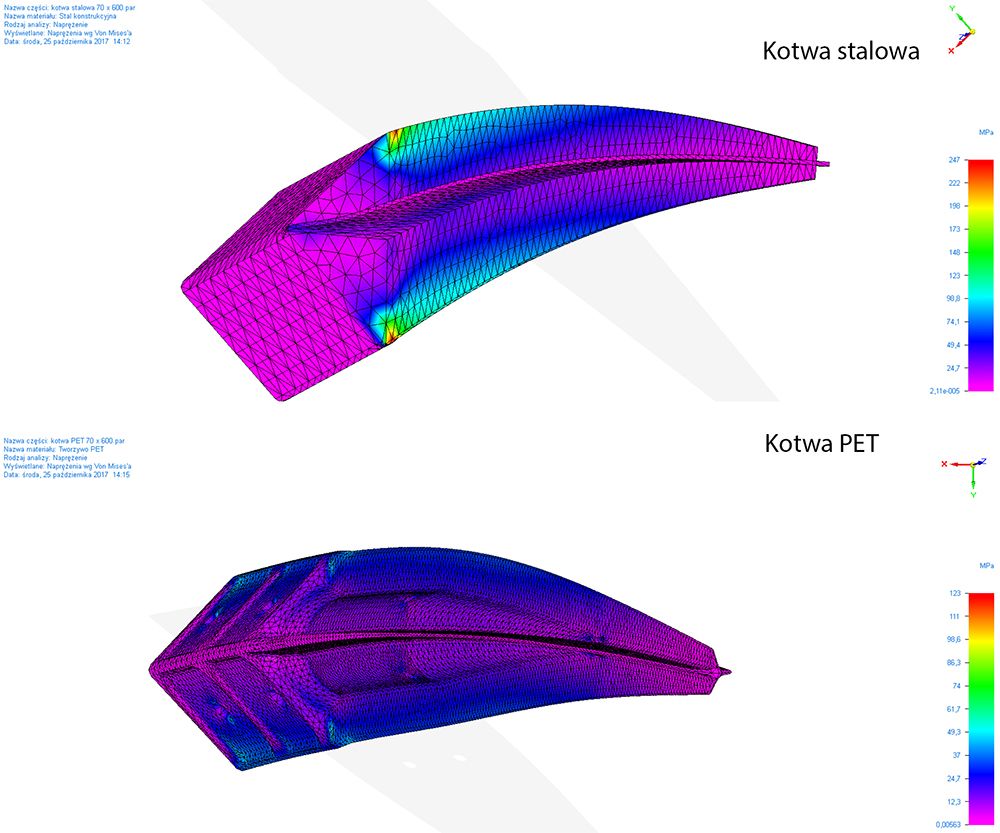

Prior to commencing manufacture of the SADDAR Eco-Anchor new model, the design is subjected to a strength analysis. Using the advanced computer programs for FEM analyses (finite element method), we determine the weakest points of the new product geometry and then correct it. Repeating this process several times we achieve an optimized model of SADDAR Eco-Anchor and thus guarantee its maximum durability. The use of high pressure injection moulding technology allows us to design SADDAR Eco-Anchors with more complex

shapes than steel anchors.

In the steel anchor, there are large areas of stress concentration at the base of the post pocket – red. This results in cracking of the welds in this area. There is no such threat in SADDAR Eco-Anchors because there are no such large areas of stress concentration. The colored scale in the lower right corner of both analyzes shows the stresses. The same lateral loads were assumed for both simulations:

- at the top of the SADDAR Eco-Anchor scale is 123 MPa.

- at the top of the steel anchor scale is 247 MPa.

We conduct our development and research work in the following areas:

- research and development work enabling the development of new technological solutions,

- modification of the composition of thermoplastics, including those filled with mineral and plant fillers,

- introducing new products into production,

- introducing previously offered products into production, but after introducing changes that increase parameters and properties.

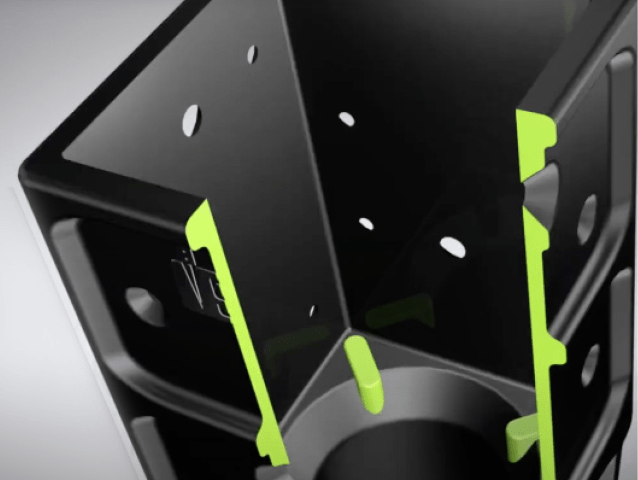

reinforcement of openings and walls in the socket for the post

SHR system (Socket’s

screw holes reinforced with additional material).

SHR reinforces the walls and screw holes in the socket for the post with a special composite sprue.

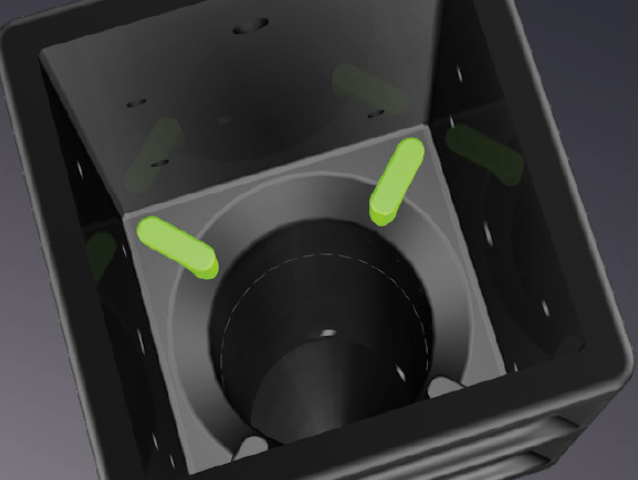

structural elements that absorb the energy of driving force – SDS (Stress Distribution System)

water drainage holes, soil softening when driving the anchor, system that distributes the mixture of water, cement and aggregate.

thickened cross-sections applied in the places of increased stresses

optimized curved ring geometry, to strengthen the structure

locking system that strengthens the anchoring of FSS Sytem (Fins and Step System to improve stability)

Our patents

The created SADDAR Eco-Anchor system is protected by copyright.

Following are the relevant industrial design numbers:

RCD 002595843-0001 do RCD 002595843-0015, 001254528-0001, 001254528-0002 Patent nr P.419267

Certificates

SDS (Stress Distribution System):

- to are specially designed elements that cushion and absorb the driving force energy

- also include thickened cross-sections in the fins of the Saddar Eco-Anchor blade, which are responsible for breaking stresses, bending stresses and impact strength

- The SDS system also prevents the accumulation of force (energy) of impacts at the bottom of the socket of the post. The SDS system also transfers the driving energy (force) directly to the fins of the SADDAR Eco-Anchor blade, eliminating the risk of damaging the Eco-Anchor at time of driving impact.

FSS System (Fins and Sep System to inprove stability) – is the system of locks strengthening the anchoring

System SHR (Socket’s screw holes reinforced with additional material).

SHR reinforces the walls and screw holes in the socket of the post with a special composite sprue. This unique plastic sprue ensures:

- stability of mounting the post in the anchor socket,

- stabilizes the screws and increases the strength of the connection

- increases the strength of the post embedded in the anchor against the pressure of lateral force

- ensures greater aesthetics of mounting

Audits

BUREAU VERITAS

(commissioned by THE HOME DEPOT USA)

TÜV Rheinland – Niemcy

(commissioned by Hornbach Germany)

Leroy Merlin Polska

Kingfisher

Intertek

(commissioned by OBI Germany)